Comprehending the Significance of Membrane Switch Over in Modern Electronics

Membrane layer buttons are indispensable components in modern-day digital gadgets. They provide a mix of performance and design that enhances individual interaction. Their lightweight and long lasting nature makes them ideal for various applications. As sectors progress, the need for customization and advanced attributes expands. Understanding exactly how membrane layer changes add to development exposes their value fit the future of electronic devices. What lies in advance for this modern technology?

The Basics of Membrane Layer Switch Over Technology

Typically overlooked, membrane layer switch technology plays a vital duty in the contemporary electronics landscape. These devices, composed of multiple layers, offer as customer interfaces for various digital items, varying from household devices to clinical devices. A typical membrane button includes a graphic overlay, a spacer layer, and a circuit layer, which are meticulously assembled to develop a practical interface.When pressure is related to the overlay, the circuit layer is finished, allowing signals to be transferred to the device. This technology is known for its versatility, enabling modification in capability, style, and form to fulfill certain customer demands. Additionally, membrane layer switches are slim and light-weight, making them ideal for applications where room is a costs. Their toughness and resistance to ecological aspects better improve their allure, ensuring they can hold up against rough conditions while preserving performance. Generally, membrane button modern technology is integral to creating easy to use and reliable digital devices

Secret Benefits of Membrane Changes

Membrane switches deal a number of vital benefits that make them a recommended option in numerous digital applications. Their design permits for a compact type aspect, making it possible for makers to produce sleek and light-weight devices. Furthermore, membrane layer switches are immune to dirt, wetness, and chemicals, which improves their resilience and long life in demanding environments. The tactile feedback provided by these switches can enhance individual experience, making them simple and instinctive to operate.Furthermore, membrane layer switches can be customized with diverse graphics and shades, enabling unique branding chances. The production procedure is typically cost-efficient, especially for high-volume production, as it reduces setting up time and streamlines style. Membrane layer switches over require marginal maintenance, contributing to lower general operational expenses. These advantages underscore their expanding popularity in contemporary electronics, where dependability and user-friendly user interfaces are necessary.

Applications Throughout Numerous Industries

The versatility of membrane switches over enables their widespread adoption throughout different sectors. In the medical area, they are commonly made use of in diagnostic devices and patient monitoring systems, offering a durable user interface resistant to pollutants. The automotive industry utilizes membrane switches for control panel controls, enhancing user experience with smooth layouts that hold up against harsh conditions. In customer electronic devices, they act as control board for tools such as microwaves and coffee machine, giving an easy to use interface that is easy to tidy. The aerospace sector employs membrane layer switches in cabin controls, where reliability and space performance are critical. Additionally, the commercial field leverages these switches in equipment and control systems to assure durable operation sought after atmospheres. This wide variety of applications highlights the versatility of membrane layer buttons, making them integral parts in improving capability and user interaction throughout varied technical landscapes.

Modification and Design Adaptability

Future Trends in Membrane Layer Change Advancement

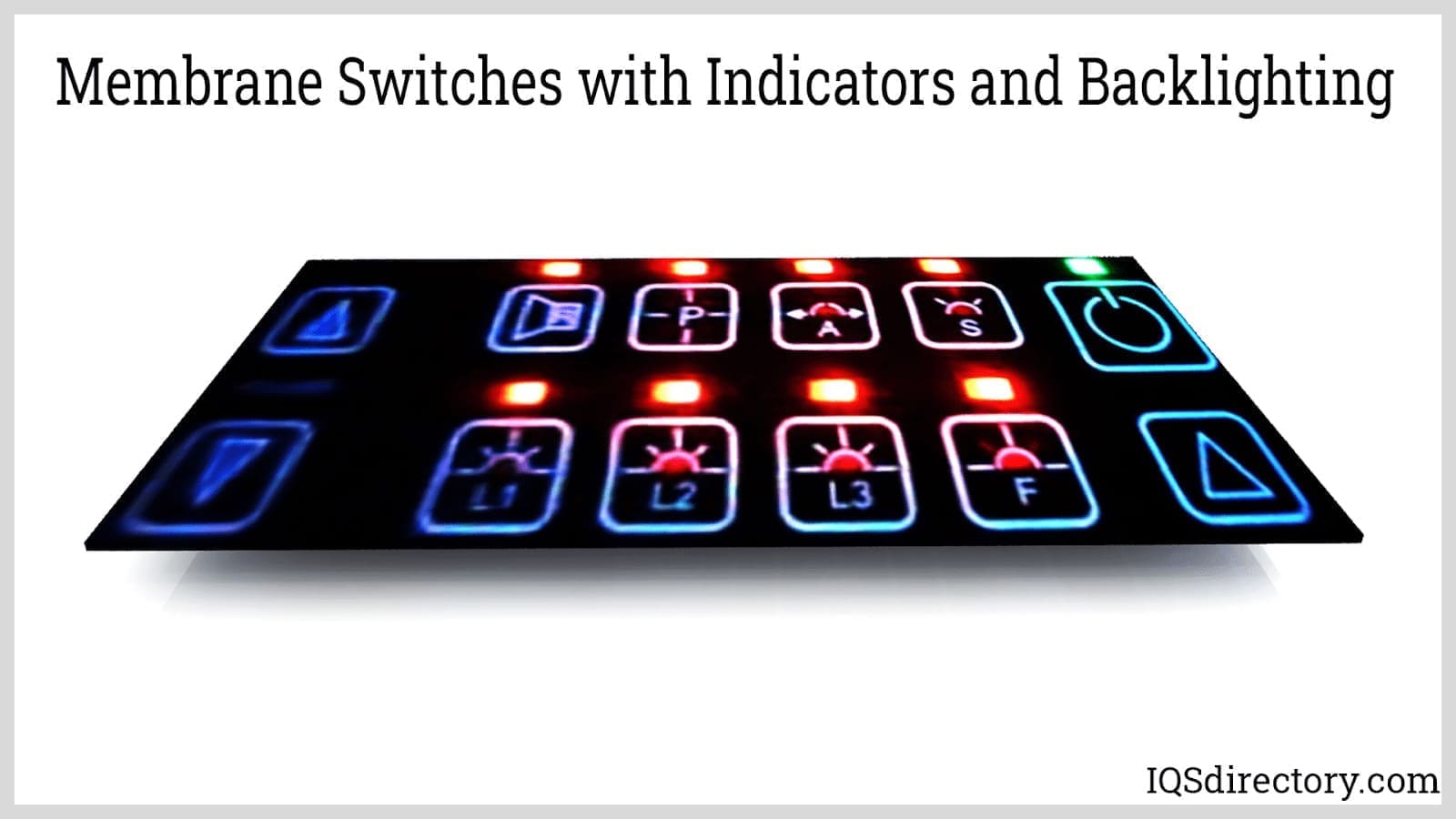

Emerging patterns in membrane layer button growth indicate an expanding focus on boosted functionality and combination with smart innovations. As customer demand for extra innovative electronic gadgets boosts, manufacturers are concentrating on producing membrane layer switches that not only offer fundamental functional roles yet likewise include functions like touch level of sensitivity, backlighting, and haptic feedback.Furthermore, advancements in products are expected to improve longevity and environmental resistance, making membrane switches over ideal for varied applications in sectors such as healthcare, auto, and customer electronic devices. The integration of capacitive touch technology is likely to become a lot more prevalent, enabling for sleeker styles and enhanced user interfaces. membrane switch.Additionally, the rise of the Web of Points (IoT) is triggering the development of membrane changes that can communicate wirelessly with other gadgets, improving interconnectivity. Overall, the future of membrane switch technology shows up appealing, driven by technology and the search of easy to use options

Frequently Asked Concerns

How Do Membrane Layer Switches Over Contrast to Typical Mechanical Switches?

Membrane layer switches, being much more space-efficient and using a sleek design, contrast with traditional mechanical switches that provide tactile responses. The former typically include customizable graphics, while the last normally guarantee resilience and dependability in various applications.

What Products Are Commonly Used in Membrane Layer Switch Production?

Membrane layer buttons are normally produced making use of materials such as polyester, polycarbonate, and printed conductive inks. These materials supply resilience, responsiveness, and flexibility, making them appropriate for various applications in digital gadgets and interface.

Can Membrane Layer Switches Over Be Fixed or Recycled?

Membrane layer buttons can typically be fixed, particularly if minor concerns occur, such as glue failure or surface damages. Total reuse is commonly restricted due to put on and prospective deterioration of materials over time.

How Do Environmental Variables Affect Membrane Layer Change Efficiency?

Environmental variables, such as temperature level, moisture, and direct exposure to chemicals, substantially influence membrane layer button efficiency. Extreme problems can cause destruction, influencing responsiveness and longevity, eventually compromising the capability of the gadget in different applications.

What Is the Typical Life Expectancy of a Membrane Layer Switch?

The typical life expectancy of a membrane button typically ranges from 1 to 5 million actuations, depending on variables such as usage regularity, environmental problems, and the materials used in manufacturing, impacting durability and performance durability. A typical membrane switch is composed of a graphic overlay, a spacer layer, and a circuit layer, which are carefully set up hop over to these guys to create a useful interface - membrane switch.When pressure is applied to the overlay, the circuit layer is completed, enabling signals to be transferred to the tool. The responsive comments offered by these switches can improve customer experience, making them simple try here and user-friendly to operate.Furthermore, membrane layer buttons can be tailored with diverse graphics and shades, permitting for one-of-a-kind branding possibilities. As consumer demand for extra sophisticated digital devices increases, producers are concentrating on developing membrane layer switches that not only serve basic functional duties however also incorporate features like touch sensitivity, backlighting, and haptic feedback.Furthermore, advancements in products are anticipated to boost longevity and ecological resistance, making membrane layer changes appropriate for varied applications in sectors such as medical care, automotive, and customer electronics. The combination of capacitive touch innovation is likely to become more prevalent, permitting for sleeker styles and improved user interfaces.Additionally, the increase of the Web of Points (IoT) is motivating the development of membrane switches over that can communicate wirelessly with various other tools, improving interconnectivity. Membrane layer buttons, being more space-efficient and using a smooth style, comparison with standard mechanical buttons that offer responsive feedback